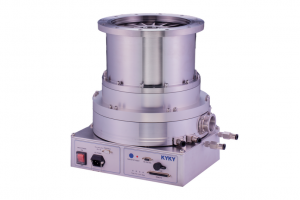

Magnetically Levitated Pump, CXF-200/1401E, Water cooling, On board

The magnetically levitated molecular pumps are the pumps of which shafting is supported by virtue of magnetic force.

Series magnetically levitated molecular pumps are vacuum generation equipment developed by KYKY for meeting application requirements for fields of modern semiconductor manufacturing, chip manufacturing, industrial plating and scientific instruments.

Technologies:

- Control Technology for Magnetic Bearing: The adopted electromagnetic is a 5-axis magnetically levitated. This design can have dynamic response and timely adjustment by means of dynamic active closed-circuit magnetic suspension control technology based on advanced international control theory, so as to guarantee such significant advantages of the high-speed shafting as stable levitated and reliable operation.

- Motor Drive Control Technology: High-efficiency high-speed DC motor and servo control system are applied to series magnetically levitated pumps, so to have maximum energy of the motor and to compensate the rotating speed of shafting automatically, thereby realizing stable start-up, reliable operation and automatic regulating function of dynamic energy.

- Carbon fiber composite rotor technology: The turbo rotors of serial magnetic suspension molecular pumps are made by compounding high-strength aluminum alloy and light-weight carbon fiber. In comparison with all aluminum alloy rotors, the turbo rotors are characterized of great reduction of weight and great improvement of strength, so that targets of high rotating speed, high performance and high reliability are achieved.

- Corrosion resisting technology: Surfaces of parts in chambers of serial magnetic suspension molecular pumps are treated with special process, so that the surfaces can resist corrosion caused by corrosive gases in semiconductor manufacturing processes for a long time. In addition, such inert gases as N2 are fully filled in shafting of the pumps to protect the low vacuum parts in the pumps, so that function of stably exhausting corrosive gases for long periods is realized.

- Heating temperature control system: Series magnetically levitated molecular pumps are equipped with an electric heater and a temperature controller, so that cooling water, air-bone heating, electric heating and heat carried by protective gases can be monitored and controlled during operation, temperature in the pumps can be maintained at some value for long term, some gaseous substances are not converted into solid substances at normal temperature and not deposited in the pumps, and requirements for special process such of etching can be met.

The advantages:

1.Zero friction during operation, and low power consumption

2.Easy to acquire really clean high vacuum and ultrahigh vacuum without lubrication for pumps

3.Capable of extracting corrosive gases for long term

4.High safety and long service life due to protection of bearings with precision ceramic balls

5.power generating function in case of sudden power-off

Specifications:

| Model | CXF-200/1401E |

| Pump Speed(l/s,Air) | 1400 |

| Compression Ratio | >1×107 |

| Ultimate Vacuum(Pa) | ≤2×10-6 |

| Inlet Flange | DN200 ISO F |

| DN200 ISO CF | |

| Outlet Flange | KF 40 |

| Rotation Speed(rpm) | 33000 |

| Run-up Time(min) | 6 |

| VIB (mm) | <0.05 |

| Backing Pump (L/s) | 15 |

| Mounting or ientation | Any |

| Cooling method | Water |

| Weight(kg)(With Controller) | 51 |

Applications:

Series magnetically levitated molecular pumps are mainly applied to fields of semiconductor manufacturing, clip manufacturing, industrial plating and scientific instruments, especially to extraction of corrosive gases existing in etch, CVD, PVD and ion implantation and gases easily coagulated at normal temperature.