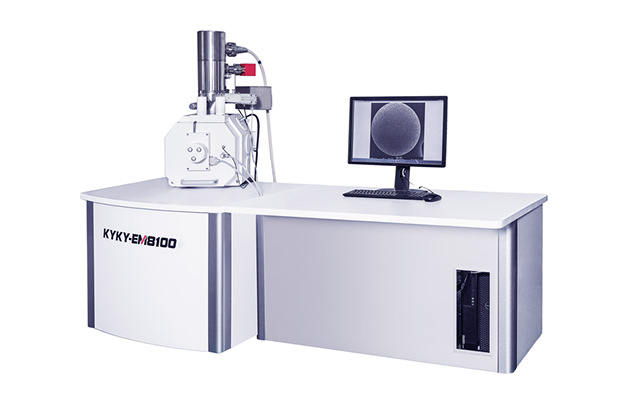

Good Quality Vacuum Gauge - Turbo Molecular Pump, FF-100/110E, Air cooling, Grease lubrication, 110L/s N2 – KYKY

Good Quality Vacuum Gauge - Turbo Molecular Pump, FF-100/110E, Air cooling, Grease lubrication, 110L/s N2 – KYKY Detail:

The grease-lubrication pump is equipped with ceramic bearing, which is usually of a self-sealed structure, consisting of a bearing inner ring, a bearing outer ring, balls, holders, a sealing end cover and lubricating grease. Shafting support structure applied to the grease-lubricated ceramic bearing has advantages of simple structure, free maintenance and low power consumption, so that molecular pump products can be installed in any orientation, and only need to be maintained once every 3-5 years in normal operating conditions.

The characteristics: the grease lubrication turbo pump

1. Stable performance.

2. Easy to operate.

3. Compact structure.

4. Multiple applications.

The applications: of grease lubrication turbo pumps are mainly in the fields:

1. solar cells, 2. Low-E glass, 3. ITO glass, 4. accelerators, 5. plasma technology, 6. lamp making, 7. vacuum leak detection

Specifications:

| Flange(In) | ISO-K/CF100 |

| Flange(Out) KF | DN25 |

| Pumping Speed( L/s) | N2:110 |

| He:110 | |

| H2:50 | |

| Ar:100 | |

| Compression Ratio | N2:108 |

| He:102 | |

| H2:102 | |

| Ar:108 | |

| Ultimated Pressure(Pa) | CF:2×10-7 |

| ISO-K:2×10-6 | |

| Max. Continuous Fore-vacuum pressure(Pa) | 200 |

| Max. Fore-vacuum Pressure | N2:300 |

| Gas Throughout (sccm) | N2:300 |

| He:240 | |

| H2:180 | |

| Ar:110 | |

| Rotation Speed ( rpm) | 42300 |

| Run-Up Time(min) | ≤3 |

| Cooling Type,Standard | Air |

| Cooling Water Consumption ( L/min) | no less than 1 |

| Cooling Water Temperature(℃) | ≤25 |

| Power Connection:Voltage (V AC) | 220±22 |

| Max.Power Consumption (W) | 300 |

| Controller Model | FD-110B |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Good Quality Vacuum Gauge - Turbo Molecular Pump, FF-100/110E, Air cooling, Grease lubrication, 110L/s N2 – KYKY , The product will supply to all over the world, such as: Canada, Jersey, Lesotho, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.