Best quality Micro Pressure Gauge - Turbo Molecular Pump, FF-200/1300E/FE, Water/air cooling, Grease Lubrication – KYKY

Best quality Micro Pressure Gauge - Turbo Molecular Pump, FF-200/1300E/FE, Water/air cooling, Grease Lubrication – KYKY Detail:

Since developing the first vertical turbo molecular pump in 1970’s, KYKY always orients to the demand-driven market, aims to meet the requirement of our customers, and continuously launches new products in the enterprise spirit of developing on innovation.

KYKY independently developed grease lubrication turbo pumps as a series of high-performance molecular pumps.

The grease-lubrication pump is equipped with ceramic bearing, which is usually of a self-sealed structure, consisting of a bearing inner ring, a bearing outer ring, balls, holders, a sealing end cover and lubricating grease. Shafting support structure applied to the grease-lubricated ceramic bearing has advantages of simple structure, free maintenance and low power consumption, so that molecular pump products can be installed in any orientation, and only need to be maintained once every 3-5 years in normal operating conditions.

The characteristics: the grease lubrication turbo pump are Compact structure, friendly operation, Wide range of application and Stable performance.

Applications:

The main applications of grease lubrication turbo pumps are in the fields of solar cells, Low-E glass, ITO glass, accelerators, plasma technology, lamp making, vacuum leak detection and other industries.

Specifications:

| Flange(In) |

DN200 CF/ISO-K |

Gas Throughout (sccm) | N2:2500 |

| Flange(Out) KF | DN40 | He:1850 | |

| Pumping Speed( L/s) | N2:1300 | H2:1450 | |

| He:1000 | Ar:950 | ||

| H2:480 | Rotation Speed ( rpm) | 24000 | |

| Ar:1250 | Run-Up Time(min) | ≤9 | |

| Compression Ratio | N2:109 | Cooling Type,Standard | Water, air(optional) |

| He:104 | Cooling Water Consumption ( L/min) | ≥1 | |

| H2:103 | Cooling Water Temperature(℃) | ≤25 | |

| Ar:109 | Power Connection:Voltage (V AC) | DC24/AC220 | |

| Ultimated Pressure(Pa) | CF:6×10-7 | Max.Power Consumption (W) | ≤500 |

| ISO-K:6×10-6 | Controller Model | TCDP-II | |

| Max. Continuous Fore-vacuum pressure(Pa) | 240 | Max. Fore-vacuum Pressure | N2:600 |

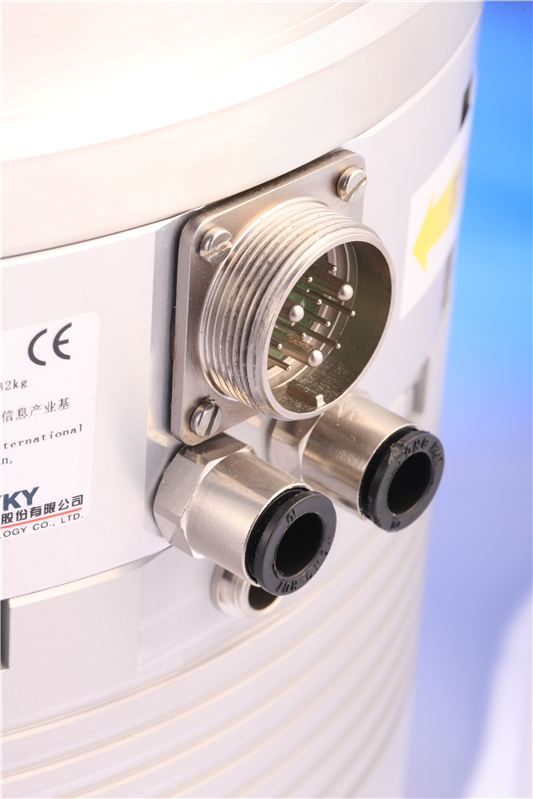

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Best quality Micro Pressure Gauge - Turbo Molecular Pump, FF-200/1300E/FE, Water/air cooling, Grease Lubrication – KYKY , The product will supply to all over the world, such as: Denmark, Russia, Uruguay, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.