2021 wholesale price Vacuum Gauges - Turbo Molecular Pump, FF-160/700E/FE, Air cooling, Grease lubrication – KYKY

2021 wholesale price Vacuum Gauges - Turbo Molecular Pump, FF-160/700E/FE, Air cooling, Grease lubrication – KYKY Detail:

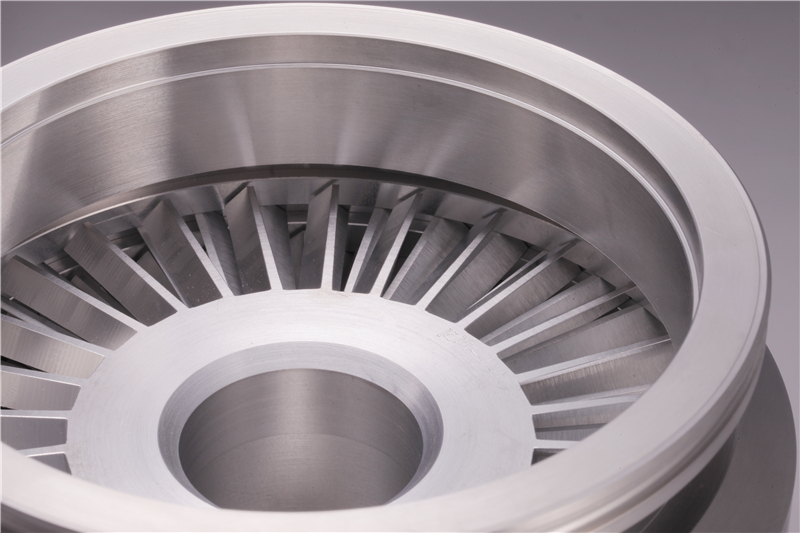

The grease-lubrication pump is equipped with ceramic bearing, which is usually of a self-sealed structure, consisting of a bearing inner ring, a bearing outer ring, balls, holders, a sealing end cover and lubricating grease. Shafting support structure applied to the grease-lubricated ceramic bearing has advantages of simple structure, free maintenance and low power consumption, so that molecular pump products can be installed in any orientation, and only need to be maintained once every 3-5 years in normal operating conditions.

The characteristics:the grease lubrication turbo pump

1. Stable performance.

2. Easy to operate

3. Compact structure,

4. Multiple applications

5. Installed in any orientation

The applications: grease lubrication turbo pumps are mainly in the fields of solar cells, Low-E glass, ITO glass, accelerators, plasma technology, lamp making, vacuum leak detection and other industries.

Specifications:

| Flange(In) |

DN150 CF/ISO-K |

Max. Fore-vacuum Pressure |

N2:550 |

| Flange(Out) KF |

DN40 |

Gas Throughout (sccm) |

N2:1400 |

| Pumping Speed( L/s) |

N2:700 |

He:1000 |

|

|

He:580 |

H2:800 |

||

|

H2:260 |

Ar:550 |

||

|

Ar:680 |

Rotation Speed ( rpm) |

36000 |

|

| Compression Ratio |

N2:109 |

Run-Up Time(min) |

≤7 |

|

He:107 |

Cooling Type,Standard |

Water/air |

|

|

H2:106 |

Cooling Water Consumption ( L/min) |

≥1 |

|

|

Ar:109 |

Cooling Water Temperature(℃) |

≤25 |

|

| Ultimated Pressure(Pa) |

CF:6×10-8 |

Power Connection:Voltage (V AC) |

220±22 |

|

ISO-K:6×10-7 |

Max.Power Consumption (W) |

≤500 |

|

| Max. Continuous Fore-vacuum pressure(Pa) |

300 |

Controller Model |

TCDP-II |

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for 2021 wholesale price Vacuum Gauges - Turbo Molecular Pump, FF-160/700E/FE, Air cooling, Grease lubrication – KYKY , The product will supply to all over the world, such as: Nigeria, Hungary, Lithuania, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.